Exceptional quality in every panel

Explore how we grew from one lamination line in 2002 to being the most comprehensive laminate panel and component supplier in the U.S.

Everything starts with a panel

We’re proud to support the RV, residential and commercial office industries as a high-volume producer focused on high-performance lamination. We fit anywhere in your supply chain because everyone’s needs are different. From panel lamination to processing and even supplying – our goal is to enhance your projects by exceeding your expectations.

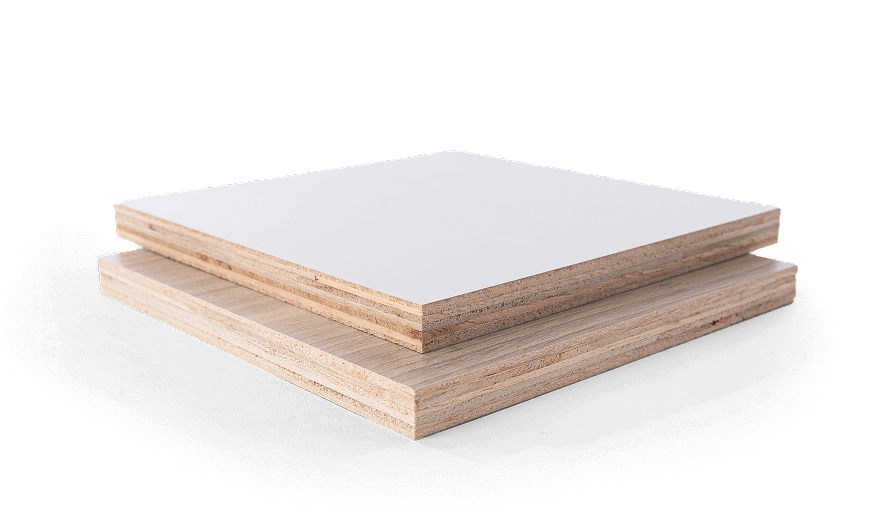

Exclusive to Funder by Genesis Products, our newest Plywood innovation has been engineered specifically to work with TFL, making it uniquely suited to the requirements of premium manufacturers. EverPly is lightweight, durable and in-demand – showcasing how the combination of two powerful materials can make a distinct difference in your products’ performance.

Lamination that knows no bounds

Across our production facilities, we offer 9 hot and cold lamination lines servicing the Midwest, East Coast, South and Southeast — most recently adding a laminator in Keysville, Virginia. With the capacity, processes and materials in place, we are at-the-ready to you help you realize your projects potential.

9 presses running up to 5,000 panels daily per hot press and 1,000 daily per cold press

1 or 2-sided lamination, standard panel sizes up to 5 ft. wide and 14 ft. long

Cut-to-size, CNC, Edgeband, Bore & Dowel

We produce domestically, yet source globally to bring you the highest quality substrates at an affordable price. As specialty laminators, our core-neutral philosophy and thin-panel expertise allow us to pair virtually any surface with any substrate.

This engineered wood product is crafted from fine wood fibers and bonded together with resin under heat and pressure. It’s often chosen for its stability, smooth finish and resistance to warping or cracking.

Valued for its strength-to-weight ratio, plywood is crafted with layers of veneer pressed together. It’s resistant to moisture and highly durable, making it ideal for cabinet and drawer boxes. We use both domestic and import plywood, including maple and birch.

This cost-effective composite material is made from wood chips and resin, compressed into panels and laminated for a smooth finish on low-impact applications.

PET Foam Core is lightweight, low-carbon and made from up to 100% recycled material, making it a game-changer for lightweight cores. This core is exclusive to us in the North American office furniture market.

We’ve partnered with National Gypsum to offer this unique VOG application designed for use in RVs, manufactured housing and other modular or mobile uses. Choose from most vinyls to achieve a premium aesthetic at an accessible price point.

We partner with leading printers and producers globally and domestically to best meet our customers’ specification needs. Doing so has enabled us to develop our Surface Synergies program with complete matches across 38 colors and five surfaces. Keep reading to see how the right surface makes all the difference.

Also known as melamine, this highly durable surface is water- and scratch-resistant with the ability to be textured for a real wood look and feel. Because it is fused to a composite wood core with heat it’s also less likely to chip or peel, giving it long-lasting appeal.

HPL is created by fusing multiple layers of paper to a composite board under high heat and pressure, creating a highly durable surface. HPL is then used for both vertical and horizontal applications like commercial furniture and countertops. We are currently stocking our own HPL as part of our Surface Synergies program.

3DL is a thermoformed vinyl that is pressed onto a substrate in a single piece, offering a seamless and strong surface. Because of its durability, it’s ideal for high-use areas like cabinet doors and drawer fronts.

Two-dimensional laminate (2DL) vinyl is a thinner, wrapping-grade version of 3DL vinyl film and is used to provide a uniform color and seamless design on components like moulding and rails.

Decorative papers, or foils, are impregnated with resin and bonded to substrates under heat and pressure. They’re an economical choice for doors, cabinet interiors and drawer components, offering a wide range of patterns and colors with a lightweight finish.

The finishing touch, edgebanding is typically made of PVC, ABS, wood veneer or melamine—and is applied to the exposed edges of panels to create a seamless look and protect the substrate from moisture and wear.

CNC, cut-to-size, edgebanding and more — we can process your panels on their own or as part of your panel program.

Discover a new face for residential cabinet doors with styles and profiles to meet everyone’s needs.

With over 70 years of experience in TFL, Funder by Genesis offers the latest in colors, textures and manufacturing advancements to help you level up your next project.

Undefined

Garage